Radio Frequency Identification (RFID) technology has become a cornerstone of modern industries such as retail, logistics, transportation, access control, and smart packaging. At the heart of every RFID tag lies the RFID inlay, the essential component that determines how effectively the tag performs in terms of read range, durability, and environmental adaptability.

Among the various factors influencing the performance of an RFID inlay, the choice of substrate material plays a decisive role. The substrate not only serves as the physical support for the antenna and chip but also directly impacts the inlay’s durability, sustainability, and overall performance in production and real-world use.

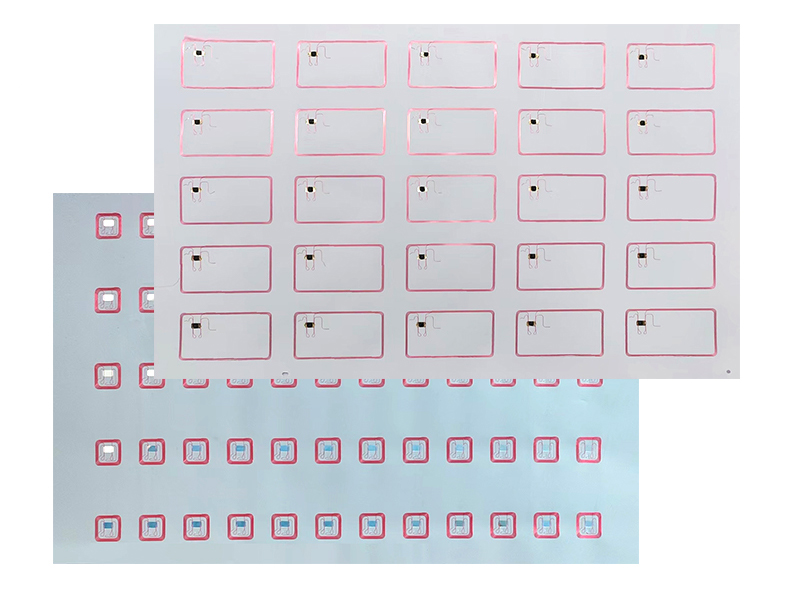

In today’s market, two substrate options stand out: PVC RFID inlays and wooden RFID inlays. PVC Inlays have been widely used for decades due to their cost efficiency and robust performance, making them suitable for large-scale deployments. Wooden RFID inlays, however, are emerging as a sustainable alternative, offering a natural aesthetic and aligning with the global push toward environmentally friendly solutions.

This article provides a detailed analysis of PVC versus wooden RFID inlays, exploring their technical characteristics, advantages and drawbacks, application scenarios, and future development trends, to help businesses make informed and strategic decisions.

What Is an RFID Inlay?

An RFID inlay is often referred to as the “core unit” of an RFID tag. It typically consists of three essential components:

Microchip (IC): Stores information and communicates with RFID readers via radio waves.

Antenna: Captures and transmits signals, enabling long-distance identification.

Substrate: The carrier layer that holds the antenna and chip in place, ensuring structural stability and compatibility with printing and lamination processes.

The choice of substrate material is far from trivial. In applications such as retail and apparel, RFID inlays must withstand frequent friction and handling. In logistics and warehousing, inlays need to survive demanding environmental conditions, such as humidity and temperature changes. For luxury packaging or smart product labeling, the focus often shifts to sustainability and visual appeal. Thus, the substrate is not merely a technical element but also a strategic decision that reflects the industry’s operational needs and brand values.

Why Do RFID Inlay Materials Matter?

The substrate acts as the backbone of the inlay, influencing critical factors such as durability, printability, environmental footprint, and aesthetic value. Each material offers a different balance of these attributes.

PVC, for example, excels in durability and water resistance, making it cost-effective and suitable for mass production. Wooden substrates, on the other hand, provide a sustainable and biodegradable option while offering distinctive branding benefits through their natural appearance.

The following comparison highlights key differences:

Criteria | PVC RFID Inlays | Wooden RFID Inlays |

Durability | Excellent; resistant to wear, moisture, and heat | Moderate; requires protective treatment |

Cost | Low to medium; scalable for mass production | Higher; suitable for niche, premium use |

Environmental Impact | Non-biodegradable; plastic waste concerns | Renewable, biodegradable, eco-friendly |

Aesthetic Value | Neutral, standard appearance | Premium, natural look with unique texture |

Applications | Access cards, tickets, logistics | Luxury packaging, eco-labels, branding |

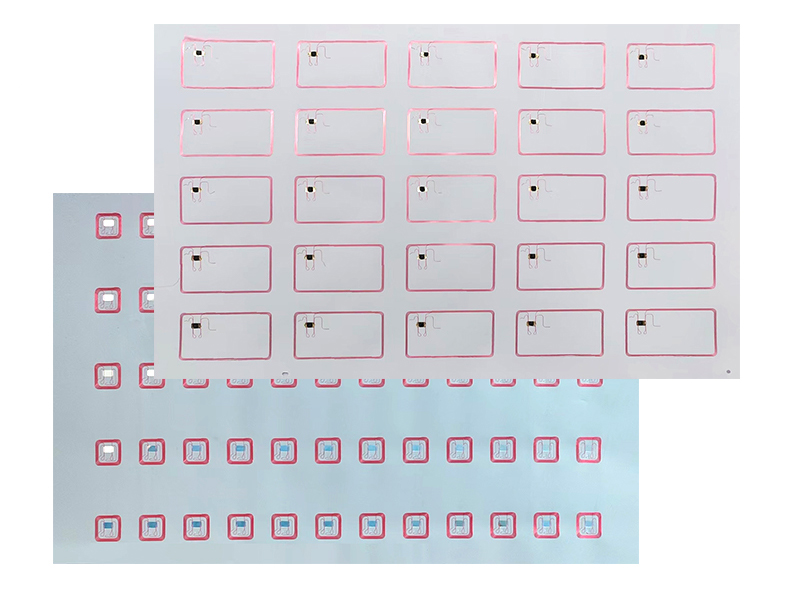

PVC (Polyvinyl Chloride) has been one of the most common substrates for RFID inlays for decades. These inlays are produced by embedding antennas and chips onto PVC sheets and then laminating them into cards, labels, or tickets.

The primary advantage of PVC Inlays lies in their durability and water resistance. They perform reliably even under frequent usage or exposure to moisture, making them ideal for applications such as access control, public transportation cards, and event tickets. Another critical strength is their cost efficiency. PVC materials are inexpensive, and the manufacturing processes are mature and highly standardized, allowing large-scale production at competitive prices. Furthermore, PVC surfaces are highly compatible with various printing techniques, enabling companies to add branding, security features, or decorative elements directly onto the cards or labels.

However, PVC Inlays are not without limitations. Their most significant drawback is their environmental impact. Being non-biodegradable, PVC contributes to plastic pollution and faces increasing regulatory scrutiny in markets where sustainability is becoming a priority. Additionally, PVC does little to enhance premium branding, which can be a disadvantage for companies that wish to emphasize eco-consciousness or luxury.

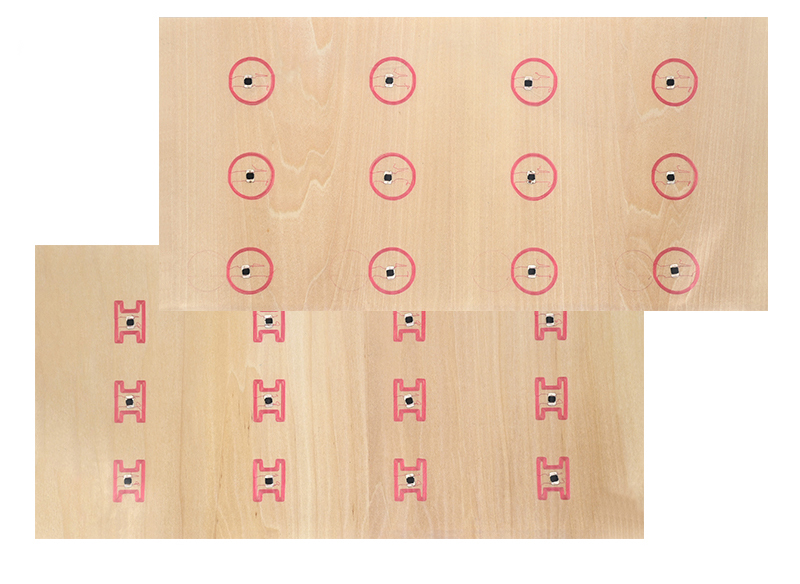

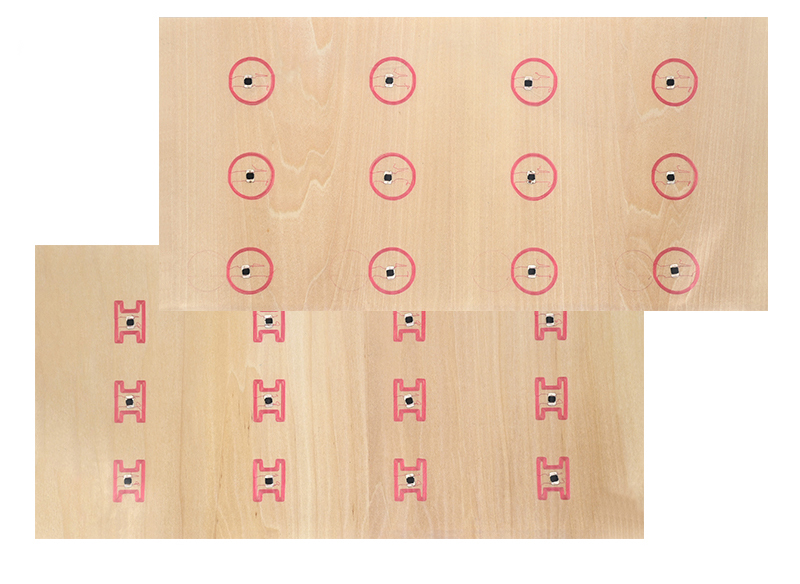

Wooden RFID inlays represent a newer, more environmentally conscious alternative to traditional substrates. These inlays are made from thin wood veneers or biodegradable wood composites, designed to deliver both technical functionality and sustainability.

The greatest strength of Wooden Inlays lies in their eco-friendliness and renewable sourcing. By significantly reducing plastic usage, they help businesses lower their environmental footprint and align with global ESG (Environmental, Social, and Governance) initiatives. In addition, Wooden Inlays are biodegradable, breaking down naturally at the end of their life cycle.

Wooden Inlays also offer a unique aesthetic advantage. Their natural texture and distinctive appearance make them highly appealing for premium applications, including luxury packaging, gift tags, branded hotel key cards, and sustainable product labeling. They not only serve a functional purpose but also enhance the brand image, conveying authenticity, sophistication, and a commitment to sustainability.

That said, wooden RFID inlays come with challenges. Their production costs are generally higher than PVC, which limits their scalability for mass-market applications. They are also more sensitive to moisture and require protective coatings for durability in humid environments. Additionally, as a relatively new product, large-scale manufacturing and supply chains for Wooden Inlays are less developed compared to PVC.

PVC vs. Wooden RFID Inlays: A Comprehensive Comparison

When businesses choose between PVC and wooden RFID inlays, several dimensions need to be evaluated:

Performance and Durability: PVC Inlays remain the stronger option for harsh or high-use environments, while Wooden Inlays are more suitable for controlled conditions and branding-focused use cases.

Environmental Responsibility: Wooden Inlays offer clear advantages in sustainability and biodegradability, aligning with eco-conscious markets and regulatory demands.

Cost and Scalability: PVC provides the lowest production cost and supports massive scalability, while Wooden Inlays serve smaller, niche markets where brand value outweighs price concerns.

Branding and Customer Perception: Wooden Inlays enhance luxury branding and eco-friendly messaging, helping businesses differentiate themselves in competitive industries.

In practice, these two materials are not direct substitutes but complementary options, each excelling in specific applications.

Application Scenarios

PVC RFID Inlays are widely used in applications where cost-effectiveness, durability, and scalability are the top priorities. Examples include:

Access Control and Smart Cards: Employee badges, hotel key cards, metro and bus passes.

Logistics and Inventory Tracking: Durable labels for crates, pallets, and storage containers.

Ticketing and Events: RFID-enabled tickets for concerts, sporting events, and transportation systems.

Wooden RFID Inlays, in contrast, are best suited for industries where sustainability, aesthetics, and brand positioning are critical. Common applications include:

Luxury Packaging: Smart labels for wine, perfumes, and high-end cosmetics.

Hospitality and Retail Branding: Eco-friendly hotel key cards and boutique retail product tags.

Green Product Labeling: Brands committed to sustainability use Wooden Inlays to emphasize their environmental values.

Future Trends in RFID Inlay Materials

The global RFID industry is undergoing a transition driven by sustainability initiatives and consumer expectations. Several future trends are worth noting:

Biodegradable Materials: Beyond wood, paper-based RFID inlays and hybrid substrates are being actively developed.

Circular Economy: Governments and organizations are encouraging eco-friendly packaging and waste reduction initiatives.

Consumer Preferences: Shoppers are increasingly willing to support brands that prioritize sustainability and eco-conscious practices.

Hybrid Innovation: Composite materials that combine durability with environmental responsibility are expected to play an important role in the near future.

As a result, while PVC Inlays will continue to dominate cost-sensitive, large-scale applications, environmentally friendly substrates like wood will capture growing market share in premium and sustainability-driven segments.

Why Choose Our RFID Inlays?

At Card Cube Group, we provide a full range of PVC and wooden RFID inlays designed to meet diverse business needs across industries.

High-Quality PVC Inlays: Cost-efficient, highly durable, and ideal for large-scale deployments.

Eco-Friendly Wooden Inlays: Sustainable, biodegradable, and visually distinctive, perfect for luxury packaging and eco-conscious branding.

Customization Options: We offer flexible sizes, antenna designs, and printing finishes to support personalized branding.

Strict Quality Control: All inlays comply with ISO/IEC standards and undergo rigorous durability and performance testing.

Global Supply Capacity: Our advanced facilities and international logistics network enable us to serve clients in retail, logistics, hospitality, manufacturing, and beyond.

Contact us today to request free samples or discuss OEM customization tailored to your business needs.

Conclusion

Selecting the right RFID inlay material is more than a technical choice—it is a strategic decision that influences cost control, environmental compliance, and brand value.

PVC Inlays remain the preferred option for high-volume, cost-sensitive applications where durability and performance are essential.

Wooden Inlays represent the future of sustainable and premium RFID solutions, providing businesses with a way to align with global green initiatives while enhancing brand perception.

As sustainability regulations become stricter and consumer expectations evolve, Wooden Inlays are expected to play an increasingly important role in the RFID industry. At the same time, PVC will continue to be indispensable for large-scale deployments where affordability and proven performance are crucial.